These links have some good closeup aerial shots of the nuke plants in Japan. This site is similar to Wikileaks, it appears.

DARPA Investigating On-Board Wii-Based Flight Control System

April 2, 2011, Guapo, Arizona– Investigators working under a DARPA grant are experimenting with an advanced flight control system using Wii technology. Professor Laurentz Fine, titular director of Pultroon University’s Ornithopter Institute (PUOI), disclosed results to the public today on recent aerospace advances at PUOI.

Professor Fine disclosed that important breakthroughs have been made in a new type of flight control system design that may influence how aircraft of the future are flown. The prototype devised at PUOI uses motion and position sensors placed on various locations on the arms, hands, and head of the flight crew. Vibration sensors on the throat are fitted to to the pilots detect the low frequencey growling sounds used for powerplant control input.

According to Professor Fine, the crew members may be placed in a prone position or may be seated in an upright position while operating the aircraft. Additional sensors may be placed on the legs and feet of the pilots and weapons officers for more channels of control input.

In a typical mission profile the pilot would don a pressure suit fitted with Wii sensors that report the position and acceleration of the limbs. The pilot would buckle into a specially designed ejection seat that would allow for the desired freedom of motion. The pilot would extend his arms horizontally to either side and issue engine commands by producing gutteral sounds on the throat sensors.

The system has only seen use in simulators at this time, but Professor Fine anticipates applications with remotely piloted vehicles and manned surveillance vehicles by 2016. Fine suggested that a model for helicopter applications was in the works, but declined to comment further. He did admit that uncommanded input caused by turbulence was a difficult problem, but progress has been made to control this issue.

Startup Failures

Having been a part of several startups that failed, I think I can speak credibly about aspects of the startup phenomenon. My friend Bill who lives in a state shaped like an oven mit sent a link to a blog written by a venture capitalist (VC). The long and short of it is that, according to this VC, too many discoveries reported in the biotech literature are based on very slender threads of experimental evidence and often have been performed by a limited number of people. He ges on to lament that the nature of grant funding may contribute to an R&D style that focuses on reporting only the best looking data that supports the hypothesis forming the basis of the grant. The basis of his commentary is his experience funding biotechstartups.

Based on my life experiences I have no doubt that his comments are reasonable.

The unspoken rule is that at least 50% of the studies published even in top tier academic journals – Science, Nature, Cell, PNAS, etc… – can’t be repeated with the same conclusions by an industrial lab. In particular, key animal models often don’t reproduce. This 50% failure rate isn’t a data free assertion: it’s backed up by dozens of experienced R&D professionals who’ve participated in the (re)testing of academic findings. This is a huge problem for translational research and one that won’t go away until we address it head on. –Bruce Booth, Life Sci VC.

The thing is, this phenomenon doesn’t have to be based on dishonesty, though sometimes it is. It is in the nature of entrepreneurs to be extremely (or rabidly) optimistic about the value of their ideas. Entrepeneurs who are specialists with some kind of standing in their field, ie., minimally having tenure or a tenure track slot at a reputable institution, can produce very convincing PowerPoint presentations and handwaving arguments to support their assertions. Especially in front of viewers and investors who are desperate to find the “next big thing”. Finding investors is a numbers game. You simply have to go out in the big, big world and talk to a great many people. Eventually you will find people who want to invest in a startup. It is a form of enchantment. And charismatic entrepreneurs learn early on that they can do this.

If you thought that this is limited to biotech or to academic entrepreneurs, you’d be wrong. I’ve seen this kind of thing up close in other areas of technology. I can say that the prospect of riches just over the horizon can move otherwise sober individuals to commit significant resources to the startup wagon train.

Especially dangerous is the entrepreneur with a patent or even a portfolio of them. Having a patent amounts to an endorsement by the US government, or so it would appear to the unwary. I’ve witnessed entrepreneurs collect and spend millions of dollars of investors money on nothing more than a patent based on handwaving. Remember, patent examiners do not require that you trot out a working model and run it for a while. Before you invest, I would recommend that you demand to be shown a working model or some other hard evidence of proof of concept.

There are several ways to set up shop in the world economy. One is to steal market share. This is the better mousetrap world of “market pull”. You develop a product or service that is superior in some way and compels customers to abandon their loyalties. You depend on taking someone else’s share of the pie.

The other way to set up shop is a bit harder. And riskier. It is the “technology push” domain and consists of introducing new capability through goods and services. It is more than taking a share of the pie- it is baking a new kind of pie. This is the realm of the paradigm shift. Examples are the introduction of petroleum, electricity, vacuum tube electronics, synthetic chemistry, semiconductors, and the internet to name some of the really big ones.

But not all technology push history is so grand. Most technology push is incremental. Marketing products that create new capability requires early investors and early adopters. And not everyone wants to be an early to the show. The trick for purveyors of technology push is to get the cash flow going by selling to early adopters.

I would offer this to those who want to be involved in a startup. Demand results from a marketing study and examine them as closely as you might the technology. If the entrepreneurs are hazy on how the sales part will look, then watch out. If they have not included money people and marketing people early in their adventure, then the investor or employee should beware. It’s not all about the technology in the startup. The entrepreneurs should be as focused on sales and marketing as the tech package. This is where academic entrepreneurs can be extremely weak.

Black Swan

Just watched the movie Black Swan directed by Darren Aronofsky and starring Natalie Portman as the lead character. It’s quite well done but it’s rated R for a reason. Mildly intense in places. Mormons and Baptists will want to select “Benji Does Dollywood” or some other wholesome meditation instead.

I have to say that Portman played the transformation of the White Swan into the Black Swan both on and off stage in a most compelling way. The actual Black Swan scene near the end is brief but spellbinding.

Lamentations on Professional Sports

I’ll admit that I’m not a sports fan. Football, baseball, basketball- it’s all just millionaires in tight pants or baggy shorts. Pre-game shows, post-game shows, hyperventilated blather, color commentary, merchandising, endlessly excessive analysis of minutae. It’s all a bit too much. It is a repetitious pageant of faux gladiators wrapped up in a glitzy Las Vegas style package promising wildly more than it delivers.

March is basketball fever time. My God! How the hell can you people sit through this stuff? Here is a proposed improvement to the game. Raise the hoop 24 inches. If you can dunk the ball, the hoop is too low. This seems obvious.

Is there a correlation between the popularity of Bud Light and the popularity of basketball? Two dreadfully bland inventions beloved by a common population? Hmmm. Panem et circenses.

Yeah, yeah. I know. How can a guy who “writes” a blog like this criticize basketball for being boring? I don’t know. I’ll have come up with a rebuttal.

Taking the dragon out for a walk

Plan on working with HF? A friend who was president of an HF manufacturing company once gave me some valuable advice. He said there are several things to do before the plastic bottle of HF arrives. First, have a well ventilated fume hood available. Next, read up on HF first aid. Try to identify a hospital ER that could cope with an HF incident. How do you do that? You call and ask questions. Get some calcium gluconate salve. Learn what to do with it. If you have an incident, you will need to get decontaminated before you arrive at the hospital, otherwise there may be delays in getting teatment by the medical staff.

Here is my personal policy. You follow your own policies. If you handle HF and do not have a specific response plan, get one in place. If you handle this acid, you need to have a plan.

Do not rely on the local fire department to know what to do. They’ll want to take charge as soon as they arrive. Time will be lost as they ignore the staff of chemical experts standing right there while they confer on a plan. I’ve seen variants of this many times. It might transpire that the firemen will be ordered to stand clear of you until their commander has a plan for dealing with the contamination. So there you’ll sit.

Your main concern in a major splash incident is to get decontaminated. Your lab buddies who are there with you need to know how help you with this so there is no delay in getting you decontaminated. Do not wait for the fire department to come decontaminate you. Strip off contaminated clothing and get under the shower pronto, even if you have to use your one good arm to drag yourself there.

HF is a weak acid with a pKa of 3.17. It is somewhat skin permeable and will cause deep tissue injury. In addition to the general hydrolytic havoc associated with an acid exposure, HF delivers fluoride which scavenges calcium and will precipitate calcium fluoride in your tissues. That is what sets an HF exposure apart. This link to Honeywell Specialty Materials is especially well written and informative.

Avoid inhalation exposure and provide for splash protection. If you are heating it, consider using a full face respirator with appropriate cartridges when opening the sash of the hood when handling the reaction mixture. Wear a long rubber or plastic gloves and apron and make sure that your lab coat is non-absorbant. Be fastidious.

Don’t be afraid of HF. It is a lot like a table saw. You just have to know how to behave around it. And like a table saw, it’ll take body parts or worse from the careless or the complacent. You have to handle it carefully every single time. Be in the moment. Don’t get distracted by talkative bystanders. Pay attention to what you’re doing.

Retorting the Auriferous Spud

Gold miners of the 19th and early 20th century had a processing advantage over todays gold miners despite all of their modern diesel powered trommels, pumps, and sluices. Some early placer miners had access to mercury or quicksilver. Auriferous fines could be concentrated in a small container with water and a few ounces of mercury would be added to extract the gold as an amalgam. Or, the concentrates could be contacted with mercury-coated copper for the same effect. Mercury coated copper pans or flat plates were often used to scavenge gold and isolate it as the amalgam.

Today, the use of mercury is strictly forbidden in mining operations around the world. But there was a time when mercury was a key part of the miners toolkit. Many extraction schemes were developed to concentrate gold into a small package. Panning or the use of a shaker table would provide nuggets and dust as concentrate. But often there was heavy black sand comingled with the gold dust. Isolation by amalgamation followed by distilling off the mercury (retorting) would provide moderately pure gold.

For example, a simple retort may be made from a pipe nipple with a cap on the bottom and a top connector attached to a long condenser tube that could be cooled with stream water. The retort vessel was set into a campfire and perhaps a cloth was wrapped around the condenser tube and wetted to knock down the mercury vapors so that they could be collected in a receiver.

Curiously, there is lore about the potato retort. My source is Eldred D. Wilson, Gold Placers and Placering in Arizona, Bulletin 168 (1961), State of Arizona, Bureau of Geology and Mineral Technology, Geological Survey Branch. In the potato retort method, a potato is cut in half and one half is hollowed out enough to accomodate an ounce or so of amalgam. The auriferous spud is wired back together and placed in the ashes of the campfire for 30-60 minutes until done. The potato is then opened to reveal a gold button in the middle. Or, so the story goes.

There were variations. Analogous to the preparation of hoe cake, digging implements were put to use in retorting duty. A potato amalgam package could be placed in a frying pan or in a shovel which would then sit in the campfire.

It’s hard to say just how effective potato retorting was compared to other methods. Admittedly, I have trouble believing that the internal temperature of the potato was high enough to do the job. It’s conceivable, perhaps, that enough Hg was cooked away to leave behind a metallic mass with some gold color. It would be interesting to try this and then get an assay.

Wilson offers this advice- don’t eat the potato.

South Pole

A friend and colleague is currently wintering over at the Amundson-Scott station on the south pole. She is sending us periodic email updates on life at the station. As they come along I’ll share bits of them. A colleague of hers posts his observations on his blog. They recently celebrated their once-per-year sunset at the equinox.

There are all sorts of station closing activities I volunteered for early on. I trained for what is called “Flight Following” to man the Comms Center in the winter whenever any flights are flying farther South than 60 degrees. South Pole’s unique position on top of the plateau makes radio reception unusually clear while closer to the coast it is often obscured. So our job is to relay messages if we hear the pilot unable to reach his coast air traffic control. I also periodically do checks in the Power Plant so those people can occasionally get a day off.

It’s almost like a commune down here. Or at least what I assume communal living would have been like in the ’60s, Kind of a fun existence for a few months. But it is damn COLD! I took my glove off to operate my camera to film sunset up on the roof of the station – our daily temps are about -80 F, with windchill well below -100 F. A gust of wind kicked up after I had been filming for less than 2 minutes and I almost couldn’t make my hand work well enough to climb back down the steps. Today there is still a blister on my pinkie finger from frostnip. Human flesh freezes within a minute when exposed to that sort of cold. –South Pole Susan

I guess I won’t be complaining about the cold anymore.

XRF Magic

We’ve been looking at hand held XRF spectrometers. If you have not been introduced to this, you may be in for a real treat. A variety of companies make them- Bruker, Thermo, and Innov-X to name a few. These things are in the low-end Lexus price category, but are they ever amazing. It’s straight out of Star Trek.

Clarke’s Third Law states that any sufficiently advanced technology is indistinguishable with magic. I gotta tell ya that these hand held XRF’s are just amazing. You point at a sample and it gives a tally of the elements present, or most of them at least. Some even have a built-in GPS you can punch to take a waypoint of the location of the sample you just analyzed out in the field. It is a great tool for mineral prospecting.

What is embarrassing is that this is the first I’ve heard of it. Our geologist friends have been using these things for a while now.

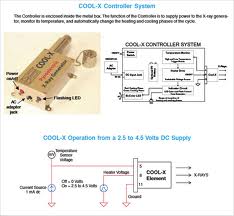

The whole thing depends on a miniature X-ray source. I’ve been looking into this. For the curious folks out there, lithium niobate- LiNbO3- is a very interesting material. Crystals of LiNbO3 have the property of pyroelectric potential. A pyroelectric crystal is one that is able to generate a polarization across the crystal faces in proportion to the temperature. A pyroelectric xtal placed on a heating/cooling block in a vacuum is able to generate a stream of electrons energetic enough that, when stopped by a copper electrode, will generate x-rays.

One manufacturer, AmpTek, produces a miniature x-ray unit called the Cool-X that has a photon output equivalent to two milliCuries, with 75 % of the flux less than 10 KeV. Elsewhere in the product literature, the output is described as 5 milliSieverts per hour. So, the user has to be a little careful with this thing. But rad safety issues aside, this is quite an amazing source. The product literature doesn’t come out and say what kind of crystals are used, but they may be a tantalate salt.

The unit does not operate continuously. It can only generate x-rays durig a thermal cycling period, The xtal starts out cool and as it’s heated, generates the electron flux that is de-accelerated by impacting the copper to produce the x-rays. The lit gives a cycling interval of 2-5 minutes. It is referred to as a Kharkov X-ray generator.

It’s magic.

Materials of Construction

One of the things you have to consider when scaling up a chemical process is the composition of the wetted or exposed surfaces in the reaction vessel, associated feed piping, gaskets, and overhead vapor spaces. Common materials of construction subject to wetting are steel (various types), glass, Hastelloy(s), tantalum, titanium, PTFE, Viton, and various polymers found in hoses.

Metal batch reactors are subject to erosion over time. Vessel walls can be tested for thickness periodically. Glass coated reactors are very useful for their broad applicability to many kinds of reactions, but have drawbacks of their own. Glassed vessels are sensitive to very high and very low temperatures as well as thermal gradients across the vessel wall. It is possible to crack the glass coating and have it flake away, exposing the underlying metal to corrosion.

We are all trained to do chemistry in glass reactors, but it should be pointed out that much chemistry can be performed in steel vessels. While you want to give some thought to the use of hydrogen, for the most part metal pots are well suited for reaction under neutral or reducing conditions. That is, metal hydrides, Na, carbanionic species BuLi and RMgX, alkoxides, etc., are well tolerated in wetted-metal pots.

Oxidizing or acid halide producing reaction systems are problematic for metal pots, however. Acidic corrosive reaction mixtures can attack the wetted metal parts of the reactor system. Acidic chlorides in particular are quite corrosive to various grades of steel. It is especially problematic when you’re talking about shell and tube condensers. The tubes are often very thin for good heat transfer, leading to the possibility of the introduction of chiller fluids into the reactor if corrosion chews through the tubes. If the chiller fluids are protic and the pot is full of MeLi, then the batch may be lost or an unplanned reactive hazard event may take place.

Condenser surfaces can be subject to more corrosion that you realize. This is the location where hot concentrated corrosive gases will condense, after all. To extend the life of the condenser, special materials of construction may be used. Tantalum and PTFE can be used when the cost is justified. With exotic materials of construction come exotic prices.

There is more to consider than corrosion. Polymer transfer lines will generate static electric hazards via the isolation of charge on nonconductive surfaces. Tranferring hydrocarbon solvents from a drum or cylinder to a reactor through nonconductive plumbing can generate significant hazardous energy and certainly enough to be incendive. Grounded metal piping can prevent part of this problem. However, discharging a flammable liquid into an air filled space may lead to an incendive discharge as well. It is important that all atmospheres over flammable liquids be inerted. While you may not be able to stop static discharges, you can certainly keep the fire triangle for being formed.

Operators are often alarmed by the sight of a glassed reactor with stirring toluene in it generating sparks by discharge through the glass coating. While this may be hard on the glassing by forming pinholes, unless there is an explosive material in solution, the lack of a complete fire triangle means that the sparks cannot lead to ignition of the toluene.

Remember not to take your material to high viscosity or dryness in a large reactor. You might end up rolling your solid material into a giant bowling ball and bending your agitator shaft. Maybe even slamming it into the reactor wall. A very expensive mistake.