Another day of grinding tedium at work. I’m rattling around in the ever-diminishing operating space of EPA regulatory compliance, bouncing off the statutory walls. Between myself, an industrial organic chemist, and a regulatory toxicologist we attempt to convince EPA that no, we will not be splashing new chemical substances (NCS) over workers and the environment. We are legally bound to be truthful and disclose any and all tox data there might be on an NCS. We have the full support of a very safety-oriented management. Our business practice and mission statement mandates that we be in compliance. We are strictly business-to-business and not a single thing goes directly to consumers or is meant to be strewn about in the environment. Everything we make is meant to have a temporary existence. Every single bit of chemical waste goes off-site to incineration.

EPA levies fines that are based on a per day, per violation basis. This can rack up the cost of an incident to a company dramatically. Civil action fines can be up to $37,500 per day per violation to a maximum of $295,000 for a Clean Air Act violation. And, even if they cannot pin a specific violation on you, there is still the General Duty clause (same as with OSHA). Companies commonly lawyer-up when dealing with EPA (and OSHA) on a violation matter because not only are there the CFRs, but case law as well to understand. Only a fool does not bring in a specialist lawyer.

All this being said, the folks who review our applications for commercial production are deeply skeptical about everything and require evidence of claims. They are statutorily obligated to approve commercial production only if there is no “unreasonable risk” to workers, the public or the environment. EPA’s use of unreasonable risk substantially relies on numerical data. In the case of missing data, they use computer models to estimate exposure if there are analogs. The human health group uses the exposure data to guide them through the maze of health effects possible.

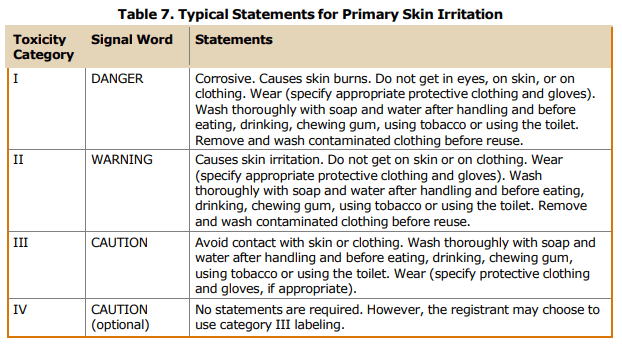

One thing I have learned from my toxicologist colleague is that health effects that I thought were easily described as “irritant” or “corrosive” are actually full of subclassifications. It’s not enough to say on the Safety Data Sheet not to breathe it or get it on you. There are categories of hazard that matter and must be ascertained by testing.

The upshot is that EPA takes exposure to new chemical substances very seriously and does their best to protect everyone and the environment from unreasonable risk. The “trick” to getting them to approve the commercial manufacture of an NCS is to have proper engineering controls in place, industrial hygiene data, appropriate PPE and compliant waste management. OSHA defines proper engineering as being Recognized And Generally Accepted Good Engineering Practices–RAGAGEP. This should be followed anyway, irrespective of regulatory compliance.

EPA has been accumulating public comment on its impending ruling on the phaseout of methylene chloride (dichloromethane, DCM, CH2Cl2). This might lump together fine chemical and pharmaceutical manufacturing with paint stripping and degreasing.