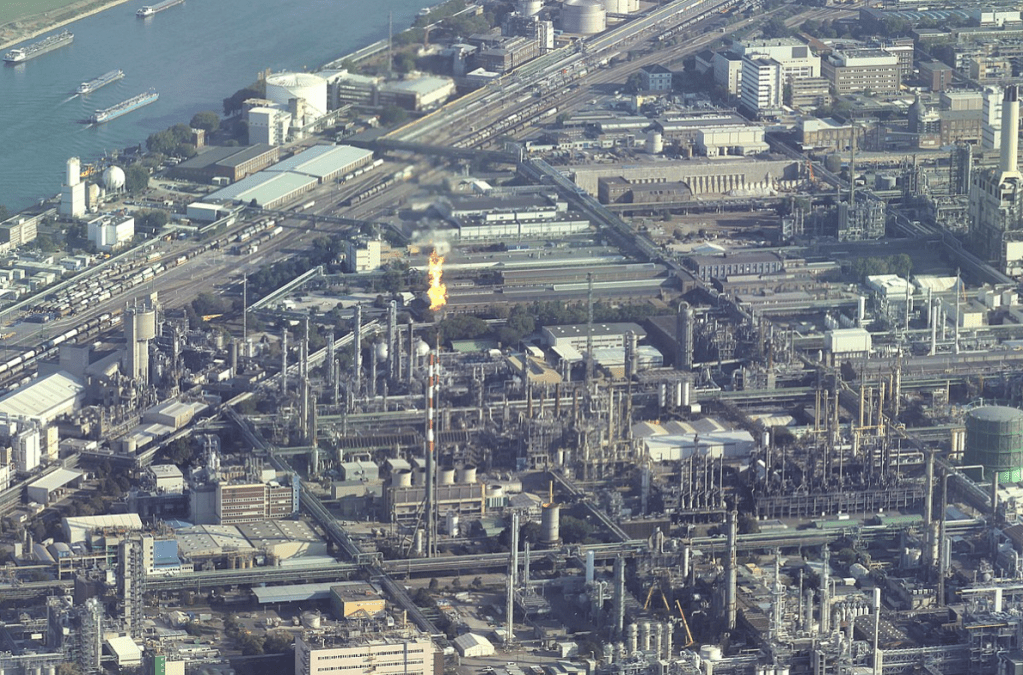

INEOS in planning to put a new ethane cracker in the ground in Antwerp, Belgium, called Project One. INEOS has reportedly raised 3.5 billion Euros for the construction. The new plant will have a carbon footprint 3 times lower than the average European steam cracker. The process will use so-called “low carbon hydrogen” to power the cracker. A cursory search of Google didn’t produce a clear definition of low carbon hydrogen. Maybe the reader has an idea. The hydrogen literature has gotten quite complicated with the large variety of hydrogen sources and technologies.

An ethane cracker removes one molecule of hydrogen from each molecule of ethane to produce one molecule of ethylene product. Of course, ethylene is the primary monomer for all of the various grades of polyethylene (a polyolefin). This uptick in capacity is likely driven by optimistic projections for increasing demand for polyolefins. Alternatively, it could be in anticipation of retiring capacity.

Other feedstocks like LPG or naphtha can be cracked to produce a different spread of unsaturated and aromatic products. Olefins produced feed into a variety of large-scale manufacturing streams.

In a cracker the ethane is diluted with steam and briefly heated to ca 850 C for a few milliseconds and then quickly quenched. Steam crackers are constructed to capture waste heat from the process to power refrigeration compressors. Production of ethylene is very energy and carbon intensive. According to Wikipedia, for every 1 tonne (1000 kg) of ethylene there are 1 to 1.6 tonnes of carbon dioxide produced, depending on the feedstock. This plant is designed to reduce carbon output.