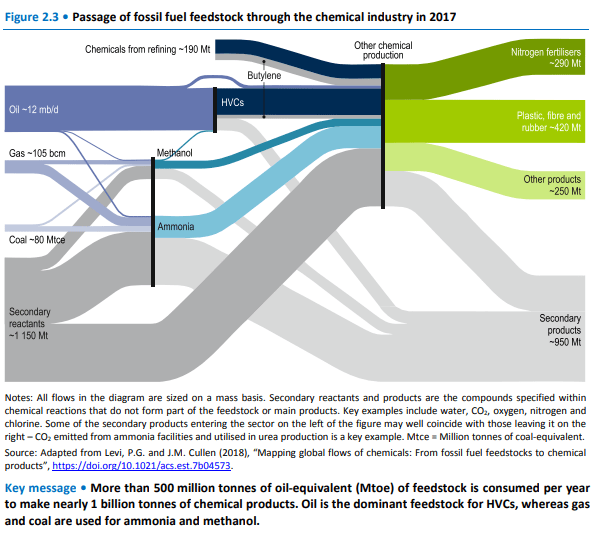

I am asking this question because the transition away from fossil fuels will have a serious knock-on effect on a very large sector of the global economy. Of the total liquid hydrocarbon production, 14 % goes to the petrochemical markets. Of natural gas production, 8 % goes to petrochemicals.

There is a serious complication connected with the idea of shutting down the combustion of hydrocarbon fuels. The elimination of oil and gas combustion activity means that crude oil production drops precipitously and therefore so would refining. Oil refineries are designed to maximize the volume of their most profitable products while minimizing their cost to manufacture. I refer to gasoline, diesel and aviation fuel. Petrochemicals come from oil and gas. Their economics ride on the coattails of fuel production to some extent in terms of scale. Refineries are physically large operations so as to operate with the maximum economy of scale. Maximum economy of manufacturing scale drives consumer prices downward.

Refineries produce much more than fuels. They produce asphalt, lubricating oil, polymer raw materials, petrochemicals for pharmaceuticals and other raw materials for thousands of products we take for granted. There are countless uses for petrochemicals beyond throw-away plastic bottles and bags. Just look around where you are sitting this very moment. Unless you are in Tierra del Fuego or Antarctica, you can’t help but see examples of hydrocarbon applications.

“Our economies are heavily dependent on petrochemicals, but the sector receives far less attention than it deserves. Petrochemicals are one of the key blind spots in the global energy debate, especially given the influence they will exert on future energy trends.” Dr Fatih Birol, Executive Director, IEA

The Future of Petrochemicals, IEA

Could refineries adapt to the loss of a large fraction of their fuels production and still produce petrochemicals? Engineering-wise, I’d say yes. But as far as economics go, that is a harder question to answer. Company officers have a fiduciary responsibility to the stockholders. This is a baked-in feature of corporate business. The promise of ever-increasing margins and volumes is part of that. Switching gears towards sustaining the petrochemical sector in the face of declining fuel sales is natural in one sense, but if it involves declining EBITDA over time, it could be disastrous for the stock market. Petrochemical prices might have to climb drastically to sustain earnings. Players in the global oil & gas market are extremely twitchy. The mere suggestion of a potential problem is enough to send prices soaring or diving. Luckily, a wind-down of fuel production will take some time during which the players might be able to compensate.

Look around you. How many consumer goods come in plastic containers or plastic film-coated paper? All of our electronic devices are built into casings of some sort, most of which have plastic or fiberglass (resin impregnated glass fiber) components. The list is endless. For many or most of these things to stay on the market, a substitute material will be needed to replace the hydrocarbon-based materials. Wooden casings for computer monitors and iPhones? What about paint? Paint is loaded with hydrocarbon components.

A vast number of products we take for granted use hydrocarbon materials in some way. Perhaps renewable plastics will scale to meet certain demands. Recycling applies only to those plastics that can be melted- the thermoplastics. Thermoset plastics like melamine cannot be melted and so cannot be recycled. Recycling only works if consumers close the recycling loop. Plastics must be carefully sorted in the recycle process. When a mixture of plastics is melted, the blend can separate like oil and water producing inferior product. National Geographic has a good web page describing recycling.

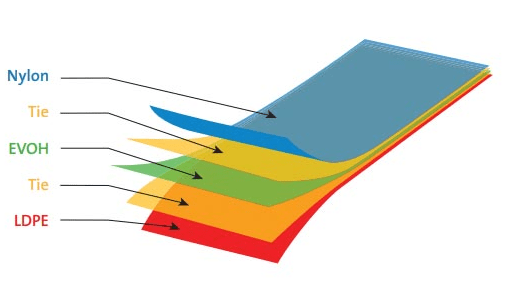

Some plastics such as clear, colorless polyethylene films are usually pure polymer. Most synthetic polymers are colorless. In general, any synthetic polymer that is colored has pigments in it. Black plastic is loaded with soot for instance. Many polymer films for packaging are multilayered with different types of polymer layered together.

Waste thermoplastic with food residues is very problematic, especially those with oil residues. Waste plastic for recycle must be clean. Multilayer plastic films are not suitable for recycling either.

Other additives such as plasticizers are present in flexible plastics like polyvinyl chloride (PVC) or other compositions where suppleness is important. Pure PVC is rigid. Additives are an industry unto its own. The varieties and grades in the plastics business is mind boggling. The variety of plastic compositions is too diverse to allow recycling of all plastics.

The point of this plastics background is to suggest that there are so many types and blends of plastic on the market- which is made even more complex by labels and additives -that the scope of polymer recycling must be narrowed to a few of the larger volume plastics. This is what is done today. LDPE, PP and PETE are the major polymers that are recycled in the US. Apparently, Japan is good at recycling. We in the US do poorly.

Polymer manufacturing is likely to continue indefinitely. There is simply too much money at stake for the big oil & gas and petrochemical players to deconstruct themselves to a large extent. They will, however, follow the consumer, but how far?

So, the question is this- for the sake of keeping a viable petrochemical stream in place while hydrocarbon fuel consumption declines, how much hydrocarbon fuel can we burn per year without exceeding the capacity of the earth to absorb the CO2 produced? We want to lower the slope of the atmospheric CO2 curve enough to achieve a reasonable steady state. The global economy depends very much on the production and use of petrochemicals. People will generally avoid economic suicide.

Where is the balance point for a sustainable production of necessary petrochemicals and the decommissioning of hydrocarbon fuel production? I certainly don’t know.