On CNBC today there was a report describing a looming shortage of trinitrotoluene, TNT, in the USA. According to this report, the USA quit manufacturing TNT in favor of importing it around 1986. Weapons-related consumption of TNT occurs both in military explosives for US stockpiles and for exported munitions. With Putin’s ridiculous war against Ukraine, America’s export of TNT-related munitions has increased, depleting the national inventory.

According to CNBC, the USA has been importing TNT from countries like Poland, Turkey, South Korea, Australia, and India. Recently, the price of TNT has increased to $20 per pound, increasing the cost of blowing rock, tanks and people to smithereens.

Some business considerations

If the competitive price for TNT is $20 per pound, then you want to ship it at a cost of at least $10 per pound. Even better would be $5-$8 per pound. This would be wonderful, but the fact is that the commodity chemical business is a high volume, low margin business. A margin squeeze is to be expected. Margins of a few dollars per pound wouldn’t be unusual for commodity chemicals.

Product below specifications can either be reworked or sold as a lower grade of product if there is demand. Commonly, below spec product can be blended with above spec product to pass QA. A TNT production plant coming online will increase the amount of product in the market, leading to depressed prices. What I’ve just said applies to the chemical industry at large, not just for explosives like TNT.

Unlike products such as bulldozers and trucks that leave the plant and go to work to create wealth, military armaments are not tools for wealth creation when used. They are consumables made for offensive or defensive destruction. Mining explosives are used to create wealth, but artillery shells are spent in conflict.

In the meantime, in Kentucky

In response to the precarious dependence on foreign vendors, the US government has awarded a contract to Repkon USA to construct a TNT manufacturing facility in Graham, KY. None other than the elderly Kentucky Senator Mitch “Grandpa” McConnell was present for the ceremony in Kentucky.

A bit of nitroaromatic history

TNT was first synthesized in 1863 by German chemist Julius Wilbrand during research in the area of synthetic yellow dyes. It wasn’t until 1891 that the explosive properties of TNT were discovered by German chemist Carl Häussermann. The earliest reported use of TNT as a military explosive was in 1902 and was used to fill artillery shells. As luck would have it, TNT is relatively insensitive and can be safely melted and poured into artillery shells or other munitions. According to Wikipedia, unlike the British explosive Lyddite, aka picric acid, TNT-filled artillery shells would not explode in contact with ships. Rather, TNT could withstand penetration of armor and then detonate internally. Artillery shells filled with the more sensitive picric acid would explode on contact with armor and explode externally, wasting its energy.

The older cousin of TNT, Picric acid, was used in the Battle of Omdurman, the Second Boer War, the Russo-Japanese War, and World War I. Picric acid was first synthesized from indigo by Peter Woulfe in 1771. It was synthesized purposely in 1841 by French chemist Jean-Baptiste Dumas. Of interest is the fact that the synthesis of indigo and other dyes was a target of much experimentation in Germany in the 1800’s.

Nitroglycerin

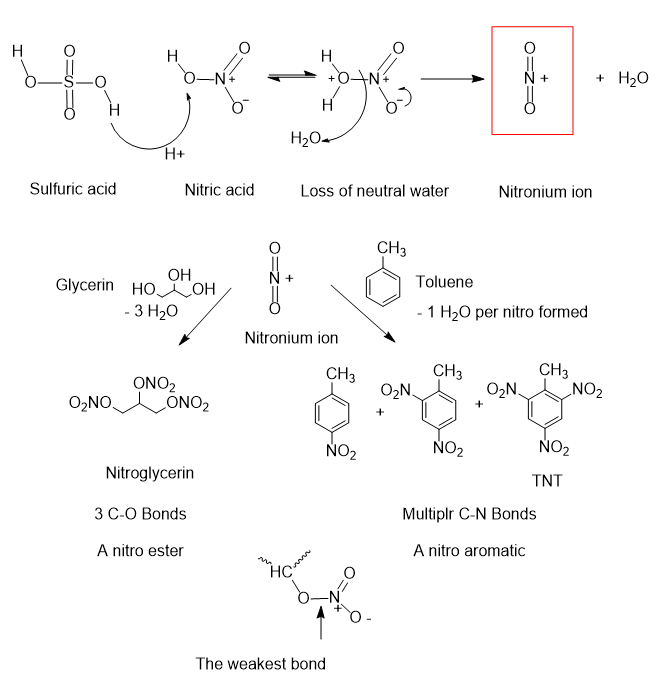

A quote from Wikipedia “The nitration of glycerin in 1846 by Ascanio Sobrero. He initially called it ‘pyroglycerine‘, and warned vigorously against its use. In fact, he was so frightened by what he created that he kept it a secret for over a year” (Wikipedia). Nitroglycerin is a nitrate ester wherein the three carbon atoms of glycerin are connected to the nitrogen through an oxygen atom. while TNT is a nitro compound with the nitrogen is connected to carbon atoms of toluene. The great sensitivity of nitroglycerin lies in the C-O-N connections while TNT and picric acid have C-N connections. Nitroglycerin is classified as a “nitro ester” while TNT and picric acid are “nitro aromatics.” The nitro ester functionality is much more susceptible to rapid disassembly by a stimulus like mechanical shock or heat.

The nitration of aromatic substances like benzene, phenol and toluene led to the introduction of powerful and relatively easy to manufacture explosives. Naturally, substances that are explosive attract great attention and have undergone a high degree of practical use to perfect.

People routinely disregard the ills of society, but when it comes to developing weapons of war, we become freaking Leonardo Di Vinci.

WWI saw the wide use of picric-acid-filled artillery shells that produced a new degree of violent destruction where used. At the same time the gas automatic machine gun, invented by Hiram Maxim, was introduced into warfare. WWI set the standard for violent death with the introduction of the Maxim machine gun and high explosives.

Interestingly, there is a medical use for nitroglycerin. It is used to treat angina. I have some at home myself, though I’ve never had to use it, thankfully.

Some words about nitration

Nitration of alcohols and aromatic compounds requires a source of -NO2, usually it’s nitric acid. However, the nitrating ability of nitric acid alone is weak, rather it must be activated to produce a more reactive form of nitrate. Sulfuric acid is a stronger acid than nitric acid and consequently is able to remove an oxygen atom by dehydration of the O-H group of nitrate anion producing water and affording a highly reactive (NO2)+ cation. The 6 electrons sandwiching the carbon skeleton of aromatic rings as with TNT, etc., are susceptible to attack by positively charged species and the (NO2)+ cation does the job. The advantage of nitric acid in all practicality is that a hydrogen atom, H+, is already attached producing a water molecule that will easily detach from the nitrogen to form the reactive species, (NO2)+. [As an aside, in chemical processing, liquids are easier and safer to transfer by pumps and piping as opposed to solid addition.]

The production of TNT might seem fairly simple- all that is needed are the cheap commodity chemicals toluene, sulfuric acid and nitric acid plus reactors and other process equipment that can resist strongly corrosive acids. The scale of the process will need to be large enough to capture the economies of scale in accordance with capital costs. Utilities like heating and chilling will be needed as well as possible on-site water treatment if allowed. And don’t forget an idiot-proof written procedure and EHS staff as well as talented management. A properly equipped analytical lab will be required for QA/QC.

More fundamentally you’ll need a remote site on which to build a plant that is supplied with sufficient electrical power as well as water and sewer. The state, county and nearby towns will insist on iron-clad assurances of worker safety and proper hazardous waste management. The state will be watching air emissions closely. Then there is finding an insurer to cover the plant and operations.

If you start a nitration operation, why not plan for products in addition to TNT? It can be unwise to operate a 1 act pony. What if the pony dies?